Products

Contact

+86 0519-86690628

Fax:+86 0519-86692128

Mail:itvrb@itvrb.com

Add:No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

产品名称: Rotary kiln carcass scanning temperature measurement system

Product Name:

Rotary kiln carcass scanning temperature measurement system

Model:

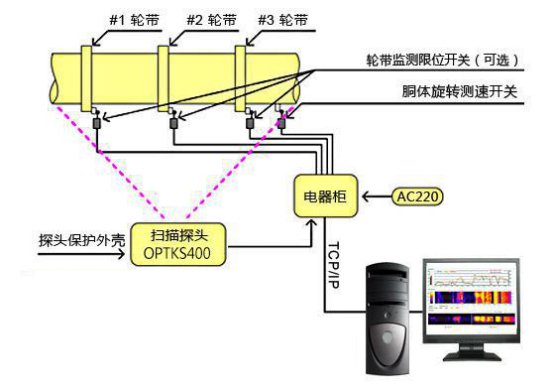

OPTKS400 (suitable for surface temperature measurement of kiln carcasses of various rotary kilns)

Main product image

Product Overview:

Rotary kiln is the key process equipment for clinker calcination, and kiln lining is the key factor for high quality, high yield, low consumption and long-term safe operation in the production of rotary kiln. Excessive temperature, excessive thermal oscillation or kiln skin formation will seriously damage the kiln lining and kiln carcass. The infrared scanning temperature measurement system OPTKS400 of the kiln carcass is an important monitoring equipment to prevent the damage of the kiln lining and the kiln carcass, ensure the safe and reliable operation of the rotary kiln, and realize the economical operation of the rotary kiln.

Our company has been committed to the research, development and promotion of infrared scanning temperature measurement system for many years. The latest generation of our company's OPTKS400 scanning temperature measurement system uses the original German imported sensor. The system can monitor and analyze the temperature information of the carcass of the rotary kiln comprehensively and meticulously during the rotation of the rotary kiln for one week, so that the operator can timely and comprehensively understand the condition of the kiln skin and refractory bricks in the kiln, so as to prevent the abnormal condition of the kiln skin in the kiln. The further deterioration provides accurate and reliable basis and timely tracking monitoring, display and alarm. In addition, other options of the system can be selected to realize functions such as measurement of shaded areas, monitoring of firing belts, belt slippage and cooling fan control.

Action

Detect hot spots due to falling, damaged or worn refractory bricks

Detect abnormal operating conditions due to irregular positions and shapes of combustion flames

Schedule optimal maintenance time

Provide complete monitoring of important parameters of kiln operation

Technical parameters:

| Performance | Metrics |

| Temperature range | 50℃~550℃ |

| Temperature Resolution | < 1℃ (200℃ bold) |

| Scanning Angle | Typical 90º or 110º |

| Spotlight | 0.3m~infinity |

| Scanning method | Electronic Array Scanning |

| Scan Frequency | 20HZ |

| Response Kiln Speed | 0.3~6r/min |

| Image refresh rate | Same as kiln speed |

| How it works | Continuous |

| Ambient temperature/humidity | -20℃~55℃ without condensation |

This system software has the following main functions:

· Real-time monitoring and analysis of kiln temperature.

· Kiln historical temperature record analysis function.

· Refractory management function for easy kiln repair and maintenance.

· Cross-section temperature quick analysis function.

· The whole kiln temperature curve analysis function.

· Kiln temperature and kiln lining thickness 3D animation in-depth analysis function.

· Fast analysis and comparison of new and old temperature data.

· Production process failure alarm function.

· Output color report.

· Kiln speed monitoring, etc.

Key words:Furnace high temperature camera (high temperature industrial TV)Special kiln thermal imager

Related applications

Feedback

-

Products

Furnace high temperature camera (high temperature industrial TV)

Special kiln thermal imager

High-performance thermal imaging camera

Furnace high temperature endoscope

Rotary kiln carcass scanning temperature measurement system

Boiler coking detector

Industrial kiln infrared temperature measurement

-

Industry

Grass

Rotary kiln

Electricity

Solid waste and waste incineration

Petrochemical

Ferrous metallurgy

-

Applications

Grass

Rotary kiln

Electricity

Solid waste and waste incineration

Petrochemical

Ferrous metallurgy

-

About Us

Profile

Honor

Equipment

-

News

Company News

Industry News

-

Contact Us

Contact

Feedback

Contact

+86 0519-86690628

Fax:0519-86692128

Fax:0519-86692128

Mail:itvrb@itvrb.com

Mail:itvrb@itvrb.com

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu