Products

Products

Contact

Fax: 0519-86692128

Email: itvrb@itvrb.com

Address:No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

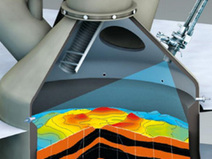

Endoscope for glass tin bath

Observation of the tin bath in a float glass production line

Category:

Keywords: High-temperature industrial special optical monitoring | Infrared thermal imaging temperature measurement system | Industrial vision

Product Brief Introduction:

Used for tin bath observation in float glass production lines

Product Name:

Glass Tin Bath Endoscope

Model:

RB-XCNK

Product Image:

Product Introduction:

In-furnace insertion type for glass furnace tin bath, the probe cover can be extended several meters into the furnace

— Observe through a 90° turning high-temperature zoom pinhole lens along the movement direction of the glass sheet, for a more intuitive and comprehensive observation of the tin bath conditions

— The probe cover can be adjusted to be parallel to the drawing roller. By adjusting the lens direction and field of view angle, several drawing rollers can be observed simultaneously.

— The image can be magnified to accurately observe a single drawing roller, its pressing depth and width into the glass sheet.

— By adjusting the lens direction and field of view angle, the distance between the tooth marks and the edge of the sheet can be intuitively observed and roughly measured on the image.

— The probe cover is made of stainless steel material, with good temperature resistance and corrosion resistance

— Special dust-proof design, the lens is not easy to accumulate dust

— Special water cooling design, can extend the service life under the same water quality conditions

— The probe cover is added with an insulation layer to reduce the impact on the temperature inside the tin bath, which is environmentally friendly and energy-saving

— Self-developed and produced high-temperature pinhole zoom lens, horizontal resolution greater than 520 lines, temperature resistance 150 degrees

— Optional manual zoom high-temperature pinhole lens to meet the observation requirements of different furnaces and different production processes

— Optional electric zoom high-temperature pinhole lens to adjust the image size range and clarity in the control room

— Optional manual feed and retract rack

— Optional electric feed and retract control rack (manual operation for large-range movement of the probe cover, electric operation for fine-tuning within a local 500mm range)

— The equipment can be controlled by DCS (electric)

Technical Parameters

Lens Clarity: Horizontal resolution no less than 520 lines

Lens Variable Focal Length: Continuously adjustable from F7 to F20.

Compressed Air (using nitrogen gas)

Total inlet pipe: G1/2

Connecting port: G1/2″ (with shut-off valve)

Inlet pressure: ≥ furnace pressure 2KPa (when the valve is open)

Inlet temperature: ≤35℃

Minimum flow rate: 0.08 cubic meters

Cooling Water

Total inlet water pipe: G3/4″

Connecting port: G3/4″ (with shut-off valve)

Inlet pressure: 0.1Mpa -- 0.4Mpa

Minimum flow rate: 30L/min

Inlet temperature: ≤35℃

Operating Ambient Temperature

On-site control box: 5~50℃

Furnace temperature: ≤1100℃ (during continuous use)

Water jacket dimensions: Length 1000mm-4000mm, outer diameter ¢89mm, inner diameter ¢46mm

Related Products

Online Message

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.