Products

Products

Contact

Fax: 0519-86692128

Email: itvrb@itvrb.com

Address:No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

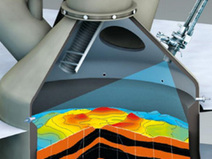

Rotary kiln thermal imager

Product Brief Introduction: The RBTemTV rotary kiln internal thermal analyzer is a temperature monitoring system used in rotary kilns, especially suitable for temperature analysis of various rotary kiln calcinations. Product Name: Rotary Kiln Thermal Imager (with automatic exit device) Model: RB TemTV series Product Image: Application Cement rotary kiln kiln head and grate cooler Lime rotary kiln kiln head Pellet rotary kiln kiln head Incineration rotary kiln Other rotary kilns Overview: The RBTemTV thermal analyzer system is a cutting-edge product that combines a conventional pyrometer and a high-temperature meter. The probe can be inserted into the rotary kiln kiln head, continuously and real-timely detecting the temperature and shape of the flame and materials inside the kiln in the central control room. Users can adjust the flame according to the temperature information to maintain the most efficient and energy-saving state of production. The system allows users to set temperature measurement zones and dangerous temperatures. If the measured temperature exceeds the dangerous temperature, users can detect system abnormalities through image and video alarm devices, and store the temperature data of the temperature measurement area for later viewing. System Overview and Features: ● Uses infrared imaging temperature measurement technology, allowing both image observation and real-time temperature measurement of the image. ● Uses water-cooled protection, the probe can be directly inserted into a 2000℃ kiln for continuous real-time monitoring. ● Probe temperature measurement range: 850℃~1800℃ (with independent intellectual property rights). ● The system can retain historical temperature data or alarm data for easy viewing during future production. Through quantifiable kiln temperature analysis, users can improve the efficiency and effectiveness of material combustion. ● Comprehensive domestic after-sales service. ● The analyzer can be used portably or fixedly installed on the rotary kiln for full-process monitoring. System Advantages: ● Accurately detects the combustion temperature of the kiln head flame and the temperature of the clinker. ● Judges the shape of the flame and optimizes combustion. ● Achieves better kiln temperature control. ● Maximizes process efficiency. ● Reduces kiln maintenance time. System Technical Parameters System Software Functions ● Maximum probe operating temperature: ≤2000℃ (under water-cooled conditions) ● Temperature measurement range: 850℃~1800℃ ● Temperature measurement accuracy: 1% error ● Field of view range: 90º ● Observation method: Direct view ● Image resolution: 640*480 ● Data output method: TCP/IP network ● Effective usable length of probe: 600mm (other lengths can be customized) ● Displays the full-frame thermal image of the rotary kiln kiln head ● Users can customize the selection of multiple points or areas for temperature display ● Regional temperature can be displayed in segments ● Temperature signals can be output as standard 4~20mA or switch signals according to user requirements ● Users can customize alarm temperature values ● The system has a function to display the temperature change curve of the set area ● The system has a function to save historical temperature data

Category:

Keywords: High-temperature industrial special optical monitoring | Infrared thermal imaging temperature measurement system | Industrial vision

Product Brief Introduction:

The RB TemTV rotary kiln in-furnace thermal analyzer is a temperature monitoring system used in rotary kilns, especially suitable for temperature analysis of various rotary kiln calcinations.

Product Name:

Rotary Kiln Thermal Imager (with Automatic Retraction Device)

Model:

RB TemTV series

Product Image:

Application

Cement rotary kiln head and grate cooler

Lime rotary kiln head

Pellet rotary kiln head

Incineration rotary kiln

Other rotary kilns

Overview:

The RB TemTV thermal analyzer system is a cutting-edge product that combines a conventional pyrometer and a high-temperature meter. The probe can be inserted into the rotary kiln head to continuously and real-time monitor the temperature and shape of the flame and materials inside the kiln from the control room. Users can adjust the flame based on the temperature information to maintain the most efficient and energy-saving production status. The system allows users to set temperature measurement zones and danger temperatures. If the measured temperature exceeds the danger temperature, users can detect system abnormalities through image and video alarm devices and store the temperature data of the temperature measurement area for later review.

System Overview and Features:

● Uses infrared imaging temperature measurement technology, allowing both image observation and real-time temperature measurement of the image.

● Uses water-cooled protection, allowing the probe to continuously and real-time monitor inside a 2000℃ kiln.

● The probe temperature measurement range is 850℃~1800℃ with independent intellectual property rights.

● The system can retain historical temperature data or alarm data for later production review. Through quantifiable kiln temperature analysis, users can improve the efficiency and effectiveness of material combustion.

● Comprehensive domestic after-sales service.

● The analyzer can be used portably or installed on the rotary kiln for full-process monitoring.

System Advantages:

● Accurately detects the combustion temperature of the kiln head flame and the temperature of the clinker.

● Judges the shape of the flame and optimizes combustion.

● Achieves better in-furnace temperature control.

● Maximizes process efficiency.

● Reduces kiln maintenance time.

| System Technical Parameters | System Software Functions |

|

● Maximum probe operating temperature: ≤2000℃ (Under water-cooled conditions) ● Temperature measurement range: 850℃~1800℃ ● Temperature measurement accuracy: 1% error ● Field of view: 90º ● Observation method: Direct view ● Image resolution: 640*480 ● Data output method: TCP/IP network ● Effective usable length of probe: 600mm (Other lengths can be customized) |

● Displays the full-frame thermal image of the rotary kiln head ● Users can customize the selection of multiple points or areas for temperature display ● Regional temperature can be displayed in segments ● Temperature signals can be output as standard 4~20mA or switch signals according to user requirements ● Users can customize alarm temperature values ● The system has a function to display the temperature change curve of the set area ● The system has a function to save historical temperature data |

Related Products

Online Message

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.