Products

Products

Contact

Fax: 0519-86692128

Email: itvrb@itvrb.com

Address:No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Boiler fouling observation instrument

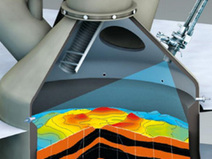

The boiler fouling observation instrument inspection system is a revolutionary system that uses high-performance multispectral technology. The images are processed using a special algorithm to remove dust.

Category:

Keywords: High-temperature industrial special optical monitoring | Infrared thermal imaging temperature measurement system | Industrial vision

Product Application Background

Some boilers have experienced fouling and coking on the heating surfaces during the co-firing of coal. A large amount of unmelted ash particles have been found adhering to the screen tubes, high-temperature superheater tubes, high-temperature reheater tubes, low-temperature reheater tubes, and low-temperature superheater tubes. Considering the characteristics of coal, some power plants use methods such as co-firing coal, soot blowing the boiler heating surfaces, and spraying nanomaterials on the furnace heating surfaces during normal operation to reduce and alleviate boiler fouling and coking. Because the specific internal conditions of the boiler are unclear and difficult to understand, the fouling and coking of the boiler's internal heating surface tubes are usually judged based on changes in flue gas and steam-water system parameters to determine the approximate location and degree of fouling and coking. This is then verified by opening the various manholes of the boiler during operation for observation. Judging the fouling and coking of the heating surface tubes based on changes in flue gas and steam-water system parameters requires high operational experience from personnel; opening the various manholes of the boiler during operation to observe the fouling and coking of the heating surface tubes has certain risks. Frequent high-frequency soot blowing causes damage to the boiler tubes, posing safety hazards to the boiler unit's operation. Using a special method and a dedicated boiler coking detector to check the coking and fouling of the various heating surfaces inside the furnace allows for precise judgment of the coking and fouling in the furnace and various heating surfaces, enabling the adoption of effective measures to control the coking and fouling of the various heating surfaces. This also allows for precise soot blowing, reducing the probability of pipe rupture due to soot blower damage to the pipes.

Solution

The boiler coking observation instrument inspection system is a revolutionary system that uses high-performance multispectral technology. Images are processed using a special algorithm to filter out dust. The unique high-temperature design allows the detector to be used online without shutting down the boiler, observing the coking conditions of the boiler water wall and superheater. This system enables coal-fired power plants to operate more efficiently, extracting more energy from coal and improving productivity. Observable installation locations include: burners, superheaters, economizers, denitrification locations, etc. With the BID-800 system, coal-fired power plant operators can directly view the fouling conditions of the boiler tubes and proactively manage the boiler. This significantly reduces the cleaning cycle and the number of shutdowns, thereby improving operational efficiency and reducing the mechanical stress that can lead to boiler tube failures.

Product Introduction

The boiler coking observation instrument uses air cooling and can be directly inserted into the boiler for observation while the boiler is in operation.

Product Application

The boiler coking observation instrument is designed for the most severe operating conditions and is particularly suitable for boilers or kilns with high flue gas and dust levels.

For example:

1. Coal-fired power plant boilers

2. Waste-to-energy and biomass power plant boilers

3. Solid waste incineration rotary kilns, etc.

System operating conditions:

Gas:

1. Pressure: 0.4 to 0.7 MPa (i.e., 4-7 kg)

2. Flow rate: 10 to 20 m3/h (m3/h is cubic meters per hour)

3. Temperature: 20 to 35 ℃

Equipment temperature resistance: 1600 ℃ (under air-cooled conditions)

Observation distance: Approximately 10 meters (may vary depending on the furnace location)

Field of view: Wide-angle range. Service life: Can be used in the furnace for an extended period

Related Products

Online Message

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.