Blog

The effectiveness and advantages of kiln thermal analyzers in the glass industry

Summary: In the glass industry, kiln temperature control and thermal analysis are particularly important. With continuous technological advancements, the application of kiln thermal analyzers has gradually become standard equipment in the industry. In particular, the emergence of body scanners has significantly improved work efficiency and product quality. So, what are the effects and advantages of kiln thermal analyzers? Let's explore this.

In the glass industry, kiln temperature control and thermal analysis are particularly important. With continuous technological advancements, the application of kiln thermal analyzers has gradually become standard equipment in the industry. The emergence of body scanners, in particular, has significantly improved work efficiency and product quality. So, what exactly are the effects and advantages of kiln thermal analyzers? Let's explore.

What is a kiln thermal analyzer?

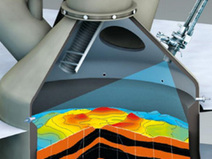

Simply put, a kiln thermal analyzer is a device used to monitor and analyze the heat distribution inside a kiln. It uses precise sensors to record the kiln's temperature changes in real-time, helping production personnel adjust temperature control parameters to ensure a stable and efficient glass production process. The body scanner, in particular, can quickly scan the temperature at different locations within the kiln, providing production personnel with intuitive data for reference.

Working principle of the kiln thermal analyzer

The body scanner uses high-precision thermocouples and infrared detectors to detect temperature changes at different locations within the kiln in real time. This process is not only fast but also accurate. Imagine baking a cake in an oven that can tell you the temperature in every corner, allowing you to adjust the cake's position to ensure even heating and avoid localized overbaking or underbaking. The kiln thermal analyzer is this kind of "smart" kiln assistant.

Application in glass production

In the glass production process, temperature uniformity is crucial. Temperatures that are too high or too low will affect the physical properties of the glass and thus the product quality. The use of body scanners allows for more refined temperature control on the production line. Through real-time data feedback, production personnel can make quick judgments, shortening decision-making time and improving production efficiency.

For example, if the temperature in a certain area is too high, production personnel can immediately adjust the heat in that area to prevent bubbles or cracks in the glass. This rapid response capability makes the entire production process smoother and reduces the defect rate.

Advantage analysis

The advantages of kiln thermal analyzers are not limited to improving production efficiency but also include the following aspects:

1. Improve product quality

Good temperature control directly determines the physical and chemical properties of glass. By using the body scanner to monitor the temperature in real time, production personnel can ensure that every step is within the optimal temperature control range, thus significantly improving the product qualification rate.

2. Reduce energy consumption

Kiln energy consumption is a major cost in glass production. Through precise temperature monitoring, production personnel can avoid unnecessary energy waste. For example, when the temperature of a certain part reaches the set value, the system will automatically adjust the heat source to ensure efficient energy utilization.

3. Enhance operational safety

In high-temperature environments, temperature anomalies can lead to equipment damage or even safety accidents. The body scanner can detect temperature anomalies in a timely manner, helping production personnel take necessary measures to reduce safety hazards.

In general, kiln thermal analyzers, especially body scanners, have demonstrated significant effects and advantages in the glass industry. They not only improve production efficiency and product quality but also reduce energy consumption and enhance operational safety. These advantages make kiln thermal analyzers an indispensable tool in modern glass production.

In the future, with continuous technological development, we can expect kiln thermal analyzers to play an even greater role in the glass industry, helping companies achieve higher levels of production management and quality assurance.

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.