Blog

The core function of the Hearth Flame TV

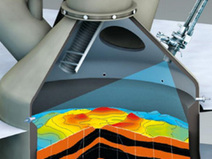

Summary: Furnace flame television is a real-time monitoring system used in high-temperature combustion equipment such as industrial boilers and heating furnaces. It is mainly used to observe the combustion state of the flame in the furnace to ensure the safety, stability, and efficiency of the combustion process. The system uses specially designed high-temperature cameras and optical components to transmit the flame image inside the furnace to the display screen in the monitoring room. Operators can visually observe parameters such as the shape, color, and distribution of the flame, and thus adjust the combustion conditions in time to prevent accidents.

Furnace flame television is a real-time monitoring system used in high-temperature combustion equipment such as industrial boilers and heating furnaces. It is mainly used to observe the combustion state of the flames in the furnace to ensure the safety, stability, and efficiency of the combustion process. The system uses specially designed high-temperature cameras and optical components to transmit images of the flames inside the furnace to the monitor in the control room. Operators can visually observe parameters such as the shape, color, and distribution of the flames, allowing them to adjust combustion conditions in a timely manner and prevent accidents.

Core Functions of Furnace Flame Television

Real-time Flame Monitoring

Directly observe the combustion of flames inside the furnace through a high-temperature camera, including the brightness, shape, and stability of the flames. This helps operators determine whether combustion is complete and whether there are any abnormal situations such as incomplete combustion or flameout.

Combustion Optimization

By observing the color and shape of the flames, it is possible to determine whether combustion is complete (e.g., whether the flames are a bright blue or golden yellow). This allows for adjustments to the fuel and air ratio to optimize combustion efficiency, reduce energy consumption, and lower pollutant emissions.

Safety Assurance

During boiler startup, shutdown, or load changes, furnace flame television can monitor the flame status in real time to prevent safety accidents (such as explosions or furnace coking) caused by abnormal situations such as flameout or flashback.

Fault Diagnosis

When combustion abnormalities occur, operators can quickly locate problems (such as nozzle blockage or insufficient fuel supply) through flame images and take timely measures to reduce downtime.

Technical Features of Furnace Flame Television

High-Temperature Design

The temperature inside the furnace is very high (usually above 1000℃). Therefore, the camera and optical components must use high-temperature materials (such as special alloys and ceramics) and be equipped with a cooling system (such as air cooling or water cooling) to ensure that the equipment operates stably for extended periods in high-temperature environments.

Explosion-proof, Dust-proof, and Corrosion-resistant

The furnace contains high temperatures, high pressure, dust, and corrosive gases. The equipment must have good explosion-proof, dust-proof, and corrosion-resistant properties to ensure safety and reliability.

High-Definition Imaging Technology

High-resolution cameras and optical lenses are used to ensure that the flame images are clear and accurate, making it easier for operators to observe and analyze.

Remote Monitoring and Data Transmission

Fiber optic or wireless transmission technology is used to transmit flame images to the control room in real time, supporting remote monitoring and data analysis to improve management efficiency.

Application Scenarios

Power Industry: Used for flame monitoring in coal-fired boilers and gas-fired boilers.

Petrochemical Industry: Used for combustion monitoring in high-temperature equipment such as oil refining furnaces and cracking furnaces.

Metallurgical Industry: Used for flame status monitoring in equipment such as blast furnaces and heating furnaces.

Waste Incineration: Used for combustion monitoring in waste incinerators to ensure complete combustion and reduce pollutant emissions.

Advantages and Value

Improved Safety: Real-time monitoring of flame status prevents safety accidents caused by combustion abnormalities.

Optimized Combustion Efficiency: Adjust combustion parameters to reduce energy consumption and pollutant emissions.

Reduced Manual Inspection: Enables remote monitoring, reducing the risk of personnel entering high-temperature environments.

Extended Equipment Lifespan: Timely detection of combustion problems prevents equipment damage due to overheating or incomplete combustion.

Furnace flame television is an indispensable safety monitoring system for industrial combustion equipment. Through real-time and intuitive flame monitoring, it helps companies improve combustion efficiency, ensure safe production, and reduce operating costs. With the development of industrial automation and intelligence, furnace flame television technology is constantly being upgraded, and in the future, it will become more intelligent and integrated, providing more reliable support for industrial production.

Previous Page

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.