Blog

Application Case Sharing of Kiln Thermal Analyzer in Chemical Industry

Summary: Today, we saw how the chemical industry is improving safety and efficiency in high-temperature environments through the combination of a kiln thermal analyzer and a high-temperature monitoring camera. Let's look forward to more applications of these technologies in the future!

Application Case Sharing of Kiln Thermal Analyzer in Chemical Industry

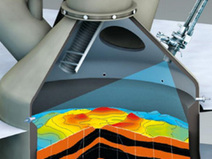

The chemical industry has always been a high-temperature, high-pressure battlefield. In this field, the emergence of kiln thermal analyzers is undoubtedly a game changer. Imagine having an intelligent assistant in your factory, constantly monitoring the temperature of the kiln and ensuring everything is within a safe range. This is the convenience that a kiln thermal analyzer can bring. In this process, the auxiliary role of high-temperature monitoring cameras should not be underestimated.

What is a kiln thermal analyzer?

A kiln thermal analyzer, as the name suggests, is a device used to analyze the temperature changes inside a kiln. It uses various sensors and technical means to monitor the temperature inside the kiln in real time, ensuring the stability of the production process. Especially in the chemical industry, slight temperature fluctuations can lead to a significant decrease in product quality, or even safety hazards.

Working principle of the kiln thermal analyzer

So, how exactly does a kiln thermal analyzer work? It is usually equipped with various temperature sensors that can transmit the temperature data inside the kiln to the monitoring system in real time. This data can not only be used to adjust the operation of the kiln, but also for long-term trend analysis. Imagine being able to predict the working status of the kiln in advance, like a weather forecast, reducing unnecessary downtime and losses. This is undoubtedly very important for any chemical enterprise.

Synergistic effect of high-temperature monitoring cameras

When using a kiln thermal analyzer, the role of high-temperature monitoring cameras cannot be ignored. This type of camera is specially designed for monitoring in high-temperature environments and can help factory personnel visually see the operation of the kiln. Through high-temperature monitoring cameras, staff can more clearly understand the status of the kiln and react quickly to ensure production safety.

Imagine, without high-temperature monitoring cameras, you can only rely on the data from the kiln thermal analyzer. Although this data is real-time, the lack of visual feedback can always make people feel uneasy. The addition of high-temperature monitoring cameras is like adding a pair of "eyes" to this process, allowing you to observe every detail of the kiln in real time and ensure everything goes as you wish.

Application Case Analysis

Let's look at some specific application cases. After adopting a kiln thermal analyzer and high-temperature monitoring cameras, a certain chemical plant increased its production efficiency by 25%. In the past, they often faced the problem of kiln temperature fluctuations, leading to production interruptions and heavy losses. However, since the introduction of these two technologies, they can not only monitor the temperature in real time, but also quickly adjust parameters when abnormalities occur, avoiding unnecessary downtime.

Another case is that a certain company, after implementing a kiln thermal analyzer, was able to increase its product qualification rate to 98%. Previously, they often had unqualified products due to improper temperature control. Through the application of these technologies, they achieved precise temperature control, thus ensuring the stability of product quality.

Summary and Outlook

In general, the combination of kiln thermal analyzers and high-temperature monitoring cameras provides strong support for safe production in the chemical industry. We can say that they are not just equipment, but also an important driving force for the progress of enterprises.

In the future, with the continuous advancement of technology, the functions of kiln thermal analyzers will become more perfect, and data analysis will become more accurate. The application of these technologies will enable the chemical industry to reach a new level in both safety and efficiency.

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.