Blog

Selection Guide for High-Temperature Industrial Televisions

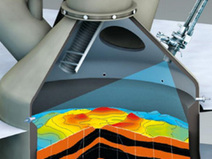

Summary: High-temperature industrial television system for monitoring industrial production processes and their environment. The system mainly consists of a camera, transmission channel, controller, and monitor. Used for real-time monitoring of power generation processes (such as boiler drum water level monitoring, combustion chamber flame monitoring), safety, and fire protection. When purchasing a high-temperature industrial television, different models should be selected according to different production environments. The following three points are the main reference factors:

Used for monitoring industrial production processes and their environment High-temperature industrial television Television system, mainly composed of camera, transmission channel, controller and monitor. Used for real-time monitoring of power generation processes (such as boiler steam drum water level monitoring, combustion chamber flame monitoring), safety and fire protection, etc. When purchasing high-temperature industrial television, different models should be selected according to different production environments. The following three points are the main reference factors:

1. According to the furnace wall thickness: The length of the lens should be 10 mm larger than the furnace wall thickness.

2. According to the furnace wall temperature: Excessive furnace wall overheating can damage the lens and equipment. When using an endoscope kiln in oil, coal, and gas kilns, only compressed air is used instead of water. The camera lens can be directly inserted into the kiln (300℃-1500℃), continuously and real-time monitoring the in-furnace heating, annealing, garbage incineration, and the combustion flame shape of the coal slag in the furnace, enabling timely detection of abnormal phenomena in the furnace and effectively preventing accidents, reducing economic losses for enterprises.

3. According to the production process requirements: The production processes of each type of furnace are different, so there are some differences in the selection. For example, the furnace temperature of a steel pipe factory, the heating furnace is generally 1200℃, and the annealing furnace is 800℃, with a wall thickness of 350mm. There are two points to consider: First, whether the steel pipe has double-pipe inlet and outlet, causing damage to the furnace; Second, observe whether the combustion of the burner flame is normal. The temperature of the glass factory kiln is generally around 1600℃, and the furnace wall thickness is generally around 700mm. There are three points to note: First, whether the bubbling is normal; Second, whether the flame combustion is normal; Third, whether the glass solution is accumulating. From the above data, it can be seen that the production processes of different types are different. Steel pipe factories generally use air cooling, while glass factories have high temperatures and harsh production environments, generally using air cooling and water cooling.

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.