Blog

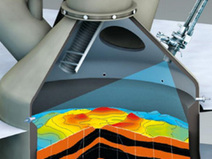

Daily maintenance of high-temperature industrial television

Summary: The clinker rotary kiln calcination is a key process, and the clinker sintering control directly affects the output and quality of cement. Controlling the kiln temperature, burner flame size, clinker lifting height, and sintering conditions through high-temperature industrial television is an important reference method for central control operators. With the development of science and technology, the high-temperature industrial television systems used in kiln heads and grate coolers are constantly being improved, with various functions and specifications such as "fixed type", "automatic protection", "near-color", "wide-angle type", and "pinhole type". The kiln head and grate cooler use two GS series high-temperature industrial television systems from our company, with automatic protection, wide-angle, and pinhole functions.

The clinker rotary kiln calcination is a key process, and the clinker sintering control directly affects the output and quality of cement. Controlling the kiln temperature, burner flame size, clinker lifting height, and sintering conditions through high-temperature industrial television is an important reference method for central control operators. With the development of science and technology, the kiln head and grate cooler used high-temperature industrial television systems are constantly being improved, with various functions and specifications such as "fixed type", "automatic protection", "quasi-color", "wide-angle type", and "pinhole type". The kiln head and grate cooler use two GS series high-temperature industrial television systems used by our company, with automatic protection, wide-angle, and pinhole functions.

System functions

The high-temperature industrial television system mainly consists of a camera unit, a transmission unit, a control unit, and a display unit. The working principles, composition, and functions of each unit are as follows:

(1) Camera unit

It consists of a camera, a lens, and a camera probe protective tube. The camera is a special camera that has undergone a high-temperature curing process and is superior to ordinary cameras in terms of high-temperature resistance and anti-interference. The lens imaging method is pinhole imaging, and the peephole in front of the lens is often between 1-2 mm. The smaller the peephole diameter, the smaller the impact of the radiant heat generated by the rotary kiln on the probe. The camera protective tube uses corrosion-resistant and high-temperature-resistant alloy materials. The cooling methods include air cooling and water cooling. According to the actual situation, our company chooses water cooling for the camera unit.

(2) Transmission device

The camera is connected to the electrical control cabinet through a high-temperature special industrial cable to prevent the high temperature of the kiln head from damaging the cable. The electrical control cabinet is connected to the integrated controller through a special twisted pair cable, and the integrated controller is connected to the color monitor through a video cable.

(3) Control and display unit

The control unit consists of an actuator, a water and gas control cabinet, and a camera controller. The pressure of the purge air from the water gas control cabinet, the pressure of the cooling water, and the temperature of the camera moving probe from the camera control cabinet are interlocked. When the working state is abnormal, the camera will automatically exit the high-temperature zone. After the working state returns to normal, the actuator will push the camera to the monitoring point through the signal given by the controller. In addition to the monitoring function, the camera controller also has functions such as providing working power, switching video signals, remotely adjusting the image, and abnormal alarms. The output signal of the controller is transmitted to the display through a video cable, and the display uses a color display that supports video input signals.

Maintenance

Maintenance is divided into daily fault maintenance and shutdown maintenance. The process equipment and production management of the new dry-process production line are relatively complete, the kiln system has a high operating rate, and there is less downtime. As an auxiliary monitoring device for the normal production of the kiln system, ensuring safe operation mainly relies on using downtime to maintain the kiln system. Daily maintenance mainly involves troubleshooting or lens blurring that suddenly occurs during operation within a short period of time. In terms of shutdown maintenance, the maintenance content includes cleaning the dust accumulated on the actuator track, adding grease, regularly draining the accumulated water in the compressed air-water separator, regularly checking the pipes and cable interfaces, and regularly checking and cleaning the camera.

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.