Blog

Abnormal handling of high-temperature industrial television

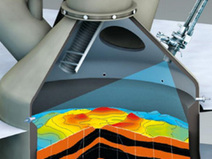

Summary: High-temperature industrial television endoscopes are widely used in metallurgy, building materials, petrochemicals, power, light industry, machinery and other fields. The lens extends into the furnace, which reduces the size of the opening in the furnace wall and keeps the camera outside the furnace wall, increasing the choice of cameras and appropriately reducing the heat dissipation requirements for the probe.

High-temperature industrial television Internal inspection furnaces are widely used in metallurgy, building materials, petrochemicals, power, light industry, machinery and other fields. The lens extends into the furnace, which can reduce the size of the furnace wall opening and keep the camera outside the furnace wall, increasing the choice of cameras and appropriately reducing the heat dissipation requirements of the probe.

Troubleshooting for high-temperature industrial television:

(1) When checking whether the camera has image output, check whether the video cable and video head are connected reliably.

(2) When the operator function keys malfunction, first check whether the operator indicator light is normal; whether the control relay is normal, and check whether the control cable is incorrectly connected.

(3) When there is no image display on the monitor, first check whether the system power supply, controller power supply, and camera power supply are normal; then check whether the display is in the "AV" state, and the display should be set to the "AV" state.

(4) When the automatic exit device fails to work properly, the system must be manually exited from the furnace wall. After cutting off the system power supply, the power should be turned on and checked in sequence according to the above procedure. Before all faults are eliminated, the system must not be pushed into the furnace wall for operation.

(5) When the monitor image is unclear or becomes smaller, this may be due to the first lens of the objective lens being contaminated by furnace dust or tar. In this case, you should first remove the protective cover from the furnace, cut off the power, open the protective cover, remove the camera, check the lens, and wipe it clean with lens paper.

(6) When the monitoring image is distorted, first check the equipment grounding to rule out repeated grounding or poor grounding; check whether the distance between the line direction and the dynamic high voltage meets the electrical specifications; finally, check whether the power supply system shares the same power supply with strong magnetic field equipment, and add an isolation transformer to supply power to the system separately.

Previous

Previous Page

Next Page

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.