Blog

Main performance and functions of the kiln body scanner

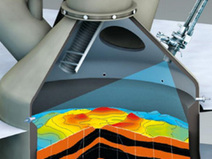

Summary: Infrared thermal scanning system (kiln body scanner, referred to as the body scanner) is a fully computer-operated, all-digital intelligent temperature imaging system. This equipment can continuously monitor the surface temperature of the rotary kiln body in real time for a long time, grasp the scaling and ring formation inside the kiln, allowing manufacturers to take effective measures in time to prevent damage to the kiln lining and kiln body, improve the operating rate of the rotary kiln, achieve economical operation of the rotary kiln, and extend the safe operating period of the kiln body.

Infrared Scanning Thermometry System (Kiln Carcass Scanner It is a fully computer-operated, fully digital intelligent thermometry imaging system. This equipment can continuously monitor the surface temperature of the rotary kiln body in real time for a long time, grasp the scaling and ring formation inside the kiln, allowing manufacturers to take effective measures in time to prevent damage to the kiln lining and kiln body, improve the operating rate of the rotary kiln, achieve economical operation of the rotary kiln, and prolong the safe operation period of the kiln body.

Main Performance

The infrared scanning thermometry system is an important detection device to ensure the safe and reliable operation of the rotary kiln. It has the characteristics of fast detection speed, accurate temperature acquisition, reliable, stable, and continuous operation under harsh environmental conditions, and also has automatic line scanning tracking function. The entire system data updates quickly, the software interface is friendly, flexible, and convenient; it can provide relevant detection information, historical records and analysis methods, as well as judgment on the status of the rotary kiln.

Main Functions

The rotary kiln infrared scanning thermometry system mainly has the following three functions: 1. Accurately measure and monitor the surface temperature of the rotary kiln body; 2. Monitor the surface temperature of the kiln body, analyze the thickness of the furnace wall in each section of the rotary kiln through software functions, and timely grasp the kiln bricks that fall off inside the kiln to effectively prevent kiln damage and prolong the safe operation period of the kiln; 3. Under intervention, minimize the risk of ring formation.

Changzhou Rongbang Automation Equipment Co., Ltd. is a professional high-tech enterprise in China specializing in high-temperature furnace special monitoring systems and infrared thermometry systems. The in-furnace high-temperature imaging system and thermal imaging system can help users improve production efficiency during production, avoid dangerous accidents in furnace pipes, and help users reduce emissions and fuel consumption during production.

Contact Us

Fax: 0519-86692128

Address: No. 108 Taihu West Road, Xinbei District, Changzhou, Jiangsu

Copyright: Changzhou Rongbang Automation Equipment Co., Ltd.